Root stresses of the thin-rimmed helical gears with symmetric and asymmetric web arrangement of β 0 = 10 and 30° were measured in the meshing process from the beginning of engagement to the end of engagement by means of the strain gage method, and then the changes of the root stresses in the meshing process were obtained. In the present paper, the root stress and the bending fatigue strength of thin-rimmed helical gears with symmetric and asymmetric web arrangement of helix angle β 0 = 10 and 30° were investigated. In the previous paper, root stresses and bending fatigue strength of thin-rimmed helical gears with symmetric web arrangement of helix angle β 0 = 20° were published by the authors ( 11-13). In order to estimate the bending strength of the thin-rimmed helical gear more exactly, it is necessary to determine effects of rim and web thickness on the root stress and the bending fatigue strength. Moreover, the deformation of rim part of thin-rimmed helical gear can be considered to be larger than that of solid helical gear. Therefore, root stresses of helical gears can be considered to be quite different from those of spur gears ( 3,5).

The line of contact of helical gear is diagonal across the tooth trace, while the line of contact of spur gear is parallel to the tooth trace. A lot of studies on root stresses of solid spur gears, solid helical gears and thin-rimmed spur gears have been published by many authors in the past ( 1-10), but studies on thin-rimmed helical gears are rarely published. Helical gears are used increasingly often as power transmitting gears, since not only can they carry larger loads because of their lower dynamic load but also their noise and vibration levels in operation are lower compared with those of spur gears. Asano, in International Gear Conference 2014: 26th–28th August 2014, Lyon, 2014 1 INTRODUCTION The usage is at own risk.Root stresses and bending fatigue strength of thin-rimmed helical gears (helix angle β0=10, 20 and 30º)

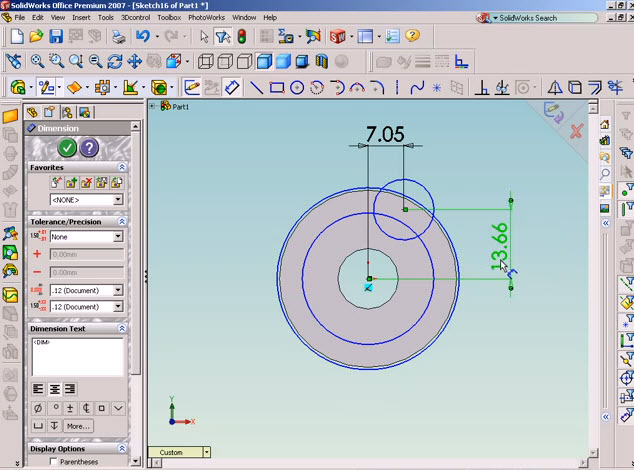

The software is tested and no errors are known, but there is no warranty for the correctness of the results and for the availability of the calculations. These online calculations are provided free of charge by MESYS AG. So a negative sign is used for the number of teeth for internal gears but all diameters are always positive. The sign convention is used as by ISO 21771. If the diameter of measurement balls or the number of teeth to span are given to zero, they are set by the calculation. This includes the measurements over balls and the base tangent length or span. Calculation of geometry for helical gear The main geometrical dimensions are calculated for a helical gear.

0 kommentar(er)

0 kommentar(er)